Mastering HVAC installation: The complete guide to mounting rails for ventilation, heating and air conditioning systems

Optimizing your HVAC installations: Mounting rails, an asset for installers.

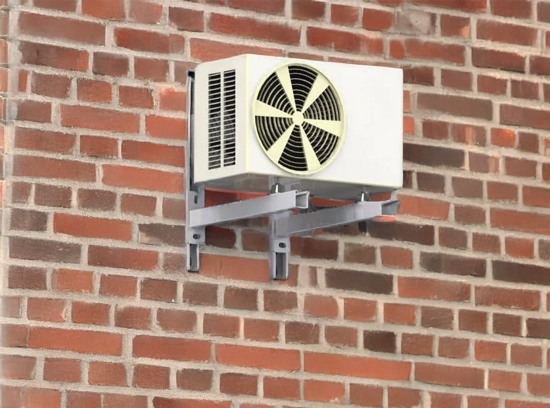

As energy efficiency and thermal comfort become priorities, HVAC (Heating, Ventilation, and Air Conditioning) systems are essential in our modern buildings. At the heart of these complex installations are mounting rails, often overlooked but essential components that radically transform the way we design and install ventilation systems.

The importance of mounting rails in HVAC installations is undeniable. Indeed, mounting rails not only facilitate the installation process by providing a structured framework for mounting HVAC components, but also contribute to improving efficiency and precision during installation. This increased efficiency translates into a significant reduction in installation time and labor costs, a considerable advantage in a sector where speed of execution is often crucial.

For HVAC installers, mastering the techniques of mounting and fixing HVAC equipment using these rails not only improves the quality of installations but also meets growing requirements for energy performance and occupant comfort. Mounting rails, such as the 41×41 and 41×82 models, offer versatility and robustness suitable for a wide variety of projects, from small residential systems to large commercial installations.

In this comprehensive guide, we will explore in detail the benefits of mounting rails for HVAC installers. We will cover the different types of rails available, the most effective installation techniques, and how these components can contribute to optimizing the performance of ventilation systems. Whether you are a seasoned professional or a beginner installer, this guide will provide you with the knowledge needed to make the most of mounting rails in your HVAC projects, enabling you to meet the challenges and opportunities that lie ahead in 2025 and beyond.

The fundamentals of mounting rails

Definition and role of mounting rails

Mounting rails are essential structural elements in modern HVAC installations. They serve as the main support for fixing and supporting ventilation duct networks, piping, and other HVAC components. Their role ensures stability, safety, and efficiency of heating, ventilation, and air conditioning systems. These rails offer a versatile and robust solution for installers, allowing quick and precise fixing of HVAC equipment. They are designed to support various loads, from light ducts to heavier equipment, while facilitating the alignment and adjustment of components.

Commonly used rail types

In the field of HVAC installations, two types of mounting rails are particularly widespread: 41×41 mm and 41×82 mm rails. These dimensions refer to the cross-section of the rail.

1- 41×41 mm rails:

2- 41×82 mm rails:

These two types of rails are generally compatible with a wide range of accessories, allowing great flexibility in the design and installation of HVAC systems.

Materials and finishes

Durability and corrosion resistance are crucial factors in choosing mounting rails for HVAC installations. The most commonly used materials and finishes are:

1- Galvanized steel:

2- Electro-zinc plated steel:

3- Stainless steel:

4- Hot-dip galvanized steel:

The choice of material and finish largely depends on the installation environment and the specific requirements of your HVAC project.

Important technical characteristics

When choosing mounting rails for an HVAC installation, several technical characteristics should be considered:

The choice of rail type in HVAC installations must be based on the specifics of the project, environmental conditions, and load requirements to ensure the longevity and efficiency of ventilation systems.

Choosing the right mounting rail for your HVAC project

Selecting the appropriate mounting rail ensures the success of your HVAC project. A judicious choice guarantees not only the stability and safety of the installation but also its long-term efficiency. Here are the key factors to consider when selecting mounting rails for your HVAC project.

Factors to consider

-> Load capacity: Precisely evaluate the total weight of the equipment to be supported and take into account potential dynamic loads, especially for vibrating equipment.

-> Installation environment:

-> Ease of installation: Consider rails with graduations for easy alignment.

-> Flexibility and adjustability: Opt for systems allowing on-site adjustments without drilling or welding.

-> Compliance with standards: Ensure that the chosen rails comply with the standards in force in your region. Check for certifications specific to the HVAC sector.

Comparison between 41×41 and 41×82 rails

41×41 rails:

41×82 rails:

The choice between these two types will depend on the specific load of your project and the complexity of the installation.

What are the essential complementary accessories for HVAC projects?

Choosing the right accessories is just as important as choosing the rails themselves. Here are some essential accessories to consider:

What factors should be considered for HVAC projects?

Choosing the right mounting rail for your HVAC project requires careful evaluation of many factors. By taking into account load capacity, installation environment, ease of mounting, and selecting appropriate accessories, you can ensure a stable, efficient, and durable HVAC installation. Remember to consult technical experts for advice and studies specific to your project.

Effective installation techniques

Efficient installation of mounting rails is crucial to ensure the performance and longevity of HVAC systems. A methodical approach can significantly improve the quality of the installation while reducing time and costs. Here is a detailed guide to best practices for installing HVAC mounting rails.

Fixing and assembly methods

1- Fixing to the support:

2- Rail assembly:

3-Mounting accessories:

4- Installation of HVAC equipment:

Tips for quick and safe installation

Quality control and safety

Frequently asked questions about mounting rail installations

41×41 rails are generally used for light to medium loads and offer good versatility. 41×82 rails are designed to support heavier loads and offer better bending resistance. Choose based on the weight of your HVAC equipment and structural constraints.

Consider the total weight of the equipment, the installation environment (indoor/outdoor, presence of moisture or chemicals), and vibration requirements. Always consult the manufacturer’s specifications and local standards.

Generally, mounting rails require little maintenance. However, it is recommended to perform regular visual inspections to check for corrosion or damage, particularly in corrosive environments.

Yes, most mounting rails are designed to be versatile. Just make sure that the chosen rail can support the weight of the equipment and withstand the specific environmental conditions (heat, cold, humidity).

Use anti-vibration supports between the rails and HVAC equipment. Ensure that the rails are properly fixed to the building structure. In some cases, the use of rubber joints or specific damping systems may be necessary.

Refer to the manufacturer’s technical specifications. The maximum load depends not only on the rail itself but also on the fixing method and the structure on which it is mounted. If in doubt, consult a structural engineer.

Yes, but make sure to choose rails treated against corrosion, such as hot-dip galvanized or stainless steel. Also check that the fixings and accessories are suitable for outdoor use.

Many modern rail systems offer integrated options for cable management. Use specific accessories such as cable clips or cable trays that attach directly to the rails.

With proper installation and maintenance, mounting rails can last as long as the HVAC system itself, typically 15 to 20 years. However, this can vary depending on the environment and the quality of the materials used.

Rails allow for precise and stable installation of HVAC equipment, which optimizes their operation. They also facilitate the installation of insulation systems and can support more energy-efficient equipment, thus contributing to the overall efficiency of the system.

Yes, several manufacturers and training organizations offer specialized courses. Check with rail suppliers or professional associations in the HVAC sector for available training options.

Belgium

Belgium  France

France  United Kingdom

United Kingdom  Bulgaria

Bulgaria  Romania

Romania  Hungary

Hungary  Czech Republic

Czech Republic  Slovakia

Slovakia