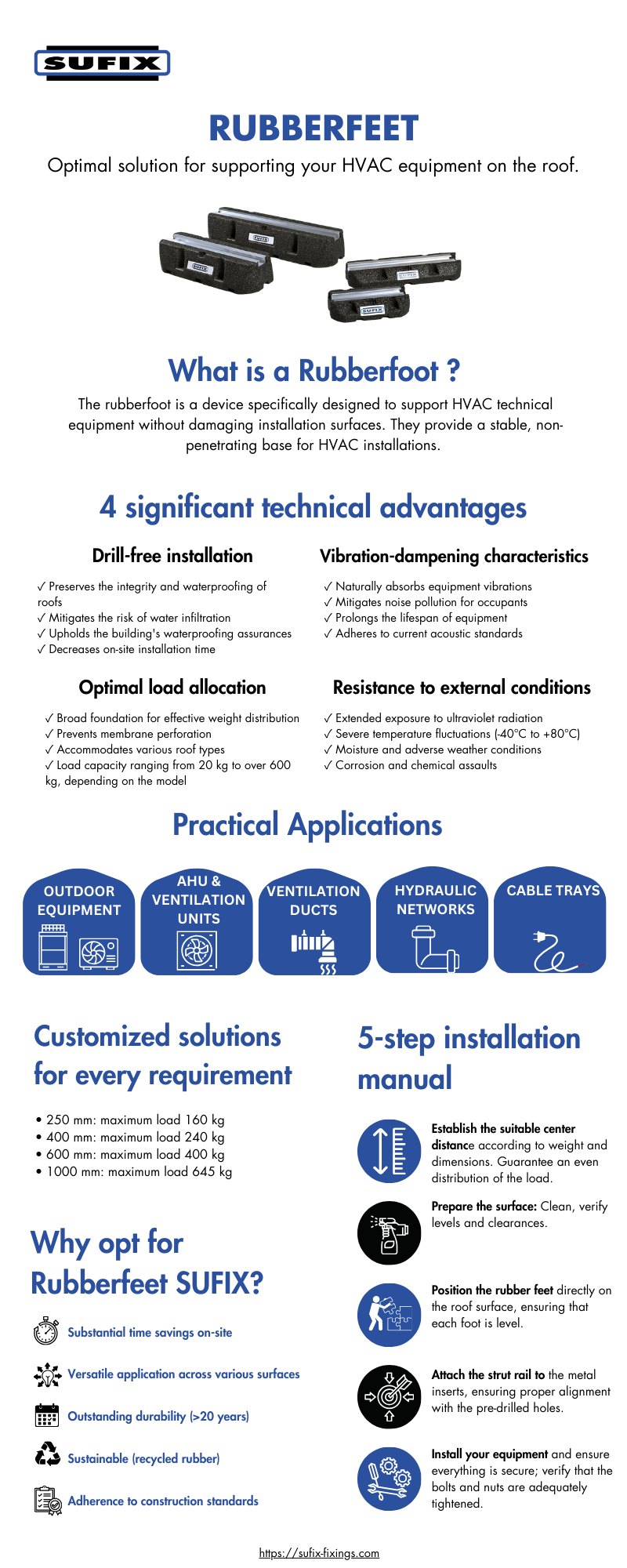

Rubberfoot: the ideal solution for supporting your rooftop HVAC equipment

Discover the Rubberfoot (rubber support feet), the ideal non-penetrating support solution for your rooftop HVAC equipment that combines stability and anti-vibration properties. This innovative mounting system has established itself as the professional standard for rooftop installations, offering both protection for waterproofing membranes and exceptional durability in all weather conditions.

In climate engineering, every detail matters to ensure efficient and durable installations. Among the often underestimated yet crucial elements: equipment supports.

Installers are constantly searching for versatile and durable support solutions for their rooftop HVAC units. Today, we highlight the rubberfoot, a popular support solution among professionals installing rooftop HVAC equipment.

What is a rubberfoot and why choose it?

The rubberfoot (or rubber support foot) is a device specifically designed to support HVAC technical equipment without damaging installation surfaces. They provide a stable, non-penetrating base for HVAC installations. Made from dense recycled rubber, it incorporates a T-bar (or strut rail) in aluminum (41×21 mm or 41×41 mm) molded directly into the rubber.

This support solution has become an industry standard in the HVAC industry for several reasons that we will detail.

Technical advantages of rubberfoot for HVAC installers

Installation without drilling: preserve roof integrity

One of the main advantages of the rubber support foot is that it requires no roof drilling. This feature is particularly valuable for:

- Avoiding water infiltration risks

- Preserving the waterproofing of roof membranes

- Maintaining building waterproofing guarantees

- Reducing installation time on site

Exceptional anti-vibration properties

The anti-vibration feet made of recycled rubber naturally absorb vibrations generated by air conditioning equipment, heat pumps, and other HVAC systems. This damping capacity allows:

- Significant reduction in vibration transmission to the building

- Decreased noise disturbance for occupants

- Extended equipment lifespan by limiting mechanical stress

- Compliance with current acoustic standards

Optimal load distribution

Thanks to its wide base and robust design, the HVAC rubberfoot support effectively distributes equipment weight over a larger surface:

- Prevention of puncturing waterproofing membranes

- Adaptation to different roof types (flat, graveled, EPDM/bitumen membranes)

- Load capacity adapted to needs (from 20 kg to over 600 kg depending on models)

Exceptional Resistance to Outdoor Conditions

Rooftop HVAC support systems are subjected to demanding environmental conditions. SUFIX rubberfeet are designed to withstand:

- Prolonged UV exposure

- Extreme temperature variations (-40°C to +80°C / -40°F to +176°F)

- Moisture and adverse weather

- Corrosion and chemical aggression

The SUFIX rubber feet range: solutions adapted to every need

At SUFIX, we offer a complete range of rubber support feet to meet the different requirements of climate engineering installers:

Mini rubber feet

Length 250 mm, max load 160 kg

Length 250 mm, max load 160 kg- Length 400 mm, max load 240 kg

Standard rubber feet

- Length 400 mm, max load 240 kg

- Length 600 mm, max load 400 kg

- Length 1000 mm, max load 645 kg

Available riser

- 100 mm riser for the 1000mm length model.

All our models are equipped with a 41×21 mm aluminum T-bar molded directly into the recycled rubber, ensuring solid and durable fixation.

Practical applications: where to use rubber feet?

HVAC equipment fixings such as rubberfoot or rubber support feet are versatile solutions for a wide range of HVAC applications. Their adaptability and efficiency make them suitable for various installations in different types of buildings and environments:

For outdoor air conditioning units, Split and VRF systems, heat pumps

Outdoor units generate significant vibrations during operation. The rubberfoot effectively isolates them while ensuring stable and secure installation on any type of roof.

For larger VRF systems with multiple outdoor units, rubber support feet can be arranged to distribute weight uniformly and maintain appropriate spacing between units. Whether it’s a membrane, metal, or concrete roof, rubber support feet can be used without compromising roof integrity.

For Air Handling Units (AHU) and ventilation units

AHUs, often bulky and heavy, require robust support. Large-capacity rubber feet offer an ideal solution for distributing these significant loads. Smaller ventilation units can be safely mounted using appropriately sized rubber support feet, ensuring stable operation and reduced noise transmission.

For ventilation ducts

Aeraulic networks installed on rooftops also benefit from the stability and protection offered by rubber supports, which keep ducts at a distance from the roof surface. By slightly raising ducts from the surface, rubber support feet help prevent moisture accumulation and corrosion. For ducts connected to air handling units or fans, rubber feet help minimize vibration transfer to the building structure.

For piping and hydraulic networks

Hydraulic and electrical networks can be easily supported thanks to the rails integrated into the rubber feet, allowing for clean and organized installation. In air conditioning systems, rubber support feet can support chilled water piping, ensuring appropriate slope and vibration isolation.

For heating networks, rubber support feet provide stable support while adapting to thermal expansion. Finally, in non-HVAC applications, rubber support feet can be used to support plumbing pipes in technical areas.

For cable trays and electrical networks

Although not directly related to HVAC, supporting electrical systems is often part of complete HVAC installations. Rubber support feet can be used to support cable trays carrying power and control wiring for HVAC systems. In some cases, rubber support feet can be employed to mount electrical panels associated with HVAC control systems.

Installation guide: how to effectively use rubber feet?

To ensure optimal installation of your HVAC equipment with HVAC rooftop rubber support feet, follow these essential steps::

- Determine the appropriate spacing based on the weight and dimensions of the equipment to be supported. Calculate the weight distribution of the unit to ensure uniform loading.

- Prepare the roof surface by cleaning the area where the rubber support feet will be placed. If working on a membrane roof, ensure the surface is dry and free of cuts or damage. For uneven surfaces, consider using additional padding or leveling materials.

- Position the rubber feet directly on the installation surface (waterproofing membrane, concrete slab, etc.). Ensure each foot is level and in full contact with the roof surface.

- Attach the strut rail to the metal inserts integrated into the rubberfoot. Measure and cut the strut rail to the required length if necessary. Align the rail with the pre-drilled holes or inserts in the rubber support feet. Secure the rail to the rubber support feet using the provided bolts or fasteners. Ensure they are tightened to the specified torque.

- Install your equipment on the support rail. Use appropriate brackets or clamps to secure the unit to the rail. Double-check that the unit is level and properly aligned.

- Secure the assembly by clamping or screwing the equipment to the rail. Check that all bolts and fasteners are tight. Ensure there is sufficient clearance around the unit for proper airflow and maintenance access.

Pro tip: For installations in windy areas, you can ballast the rubber feet with gravel or use suitable fasteners without piercing the waterproofing membrane.

The rubberfoot or support foot for HVAC equipment in infographic

FAQ: Everything you need to know about rubberfoot support feet

SUFIX recycled rubber supports are designed to last more than 20 years under normal outdoor use conditions. The material does not degrade under the effects of UV or temperature variations.

Yes, for roofs with a slight slope (up to 5°), rubber feet can be used. For steeper inclines, complementary fixing solutions may be necessary.

No, this is one of the major advantages of this solution. Once installed, rubber supports require no specific maintenance.

Depending on the models, capacities vary from 160 kg to more than 645 kg per support. For heavy equipment, it is recommended to use multiple supports distributed to balance the load.

Yes, rubber supports are compatible with most waterproofing membranes used on roofs: bitumen, EPDM, PVC, TPO, etc. The rubber does not chemically interact with these materials.

The calculation depends on the weight of the equipment to be supported and its distribution. As a general rule, plan for one support every 1 to 1.5 meters for linear installations, and a minimum of 4 supports for outdoor air conditioning units.

Absolutely! Their ease of installation and removal makes them an ideal solution for temporary installations or equipment that might need to be moved later.

Trust SUFIX to effectively support all your HVAC equipment!

27460 Alizay

Horaires

8h00 - 12h00, 13h30 - 17h30 Web https://www.ouestisolventil.fr/ Direction

1930 Zaventem, Belgium Web https://www.cairox.be/ Direction

BITEP Industrial Park, 2040 Budaörs, Hungary Web https://cairox.hu/ Direction

013604 Bucharest, Romania Web https://www.cairox.ro Direction

Manchester M24 2RW, United Kingdom Web https://www.sksales.co.uk/ Direction MAS : Mechanical Air Supplies LTD

Leatherhead KT22 7DG

United Kingdom Web https://masltd.com/ Direction

8045 Graz, Austria Web https://www.profant.at Direction

54293 Trèves Web https://blh-trier.de/ Direction

Belgium

Belgium  France

France  United Kingdom

United Kingdom  Bulgaria

Bulgaria  Romania

Romania  Hungary

Hungary  Czech Republic

Czech Republic  Slovakia

Slovakia